Generation systems and electric machines

The use of Medium-Voltage DC Current (MVDC) electric distribution systems on large cruise liners is opening up interesting new perspectives as regards the performance of electric machinery for power generation. In the field of ship design, the most significant performance indicators relate to the construction technology, and the efficiency, size and reliability of the electric generators.

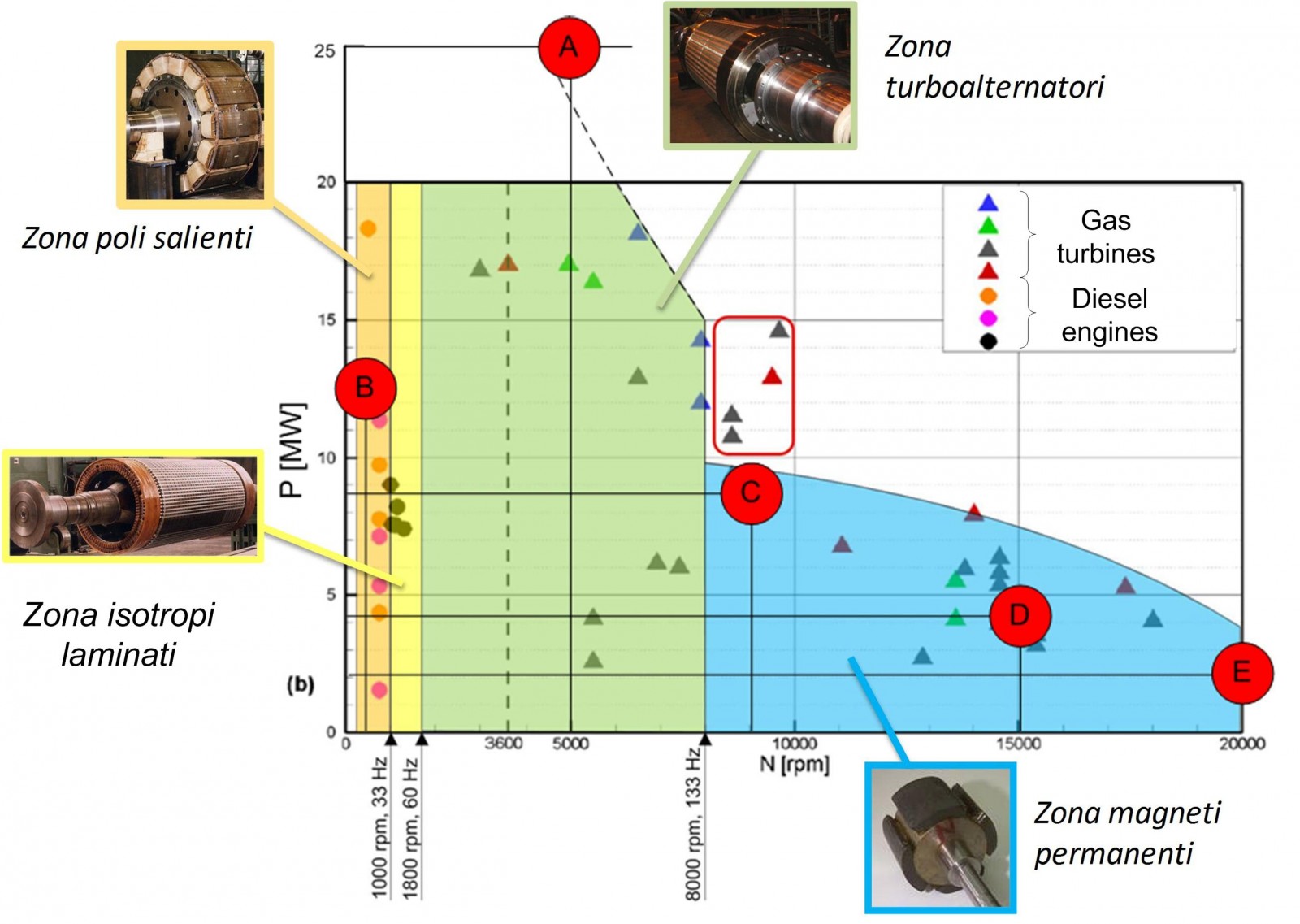

Different areas of the power-speed plane can be covered by electric generators featuring various technologies. In the same plane, triangular and circular markers indicate turbines and diesel engines suitable for use as prime movers.

Construction technologies

The use of MVDC networks allows for new kinds of high-speed and ultra-high-speed prime movers (gas turbines) to be used in addition to conventional internal combustion engines. The technology of the electric generators compatible with high-speed gas turbines is substantially different the traditional combination of alternator and internal combustion engine. The turbo-alternator and permanent-magnet construction technologies are particularly important. Although not yet consolidated for shipboard use, these types of electric machine are widely used in other environments (in both industry and power generation) and no particular criticalities are expected to arise with regard to their future integration into the ship’s power system.

Generation machinery efficiency

The efficiency of an electric generator, remains very high – typically higher than 97% – compared to that of a prime mover regardless of the technology employed. The impact of the electric generator on the overall shipboard energy consumption can be deemed negligible, regardless of whether an AC or DC distribution system is chosen.

Generation machinery size and weight

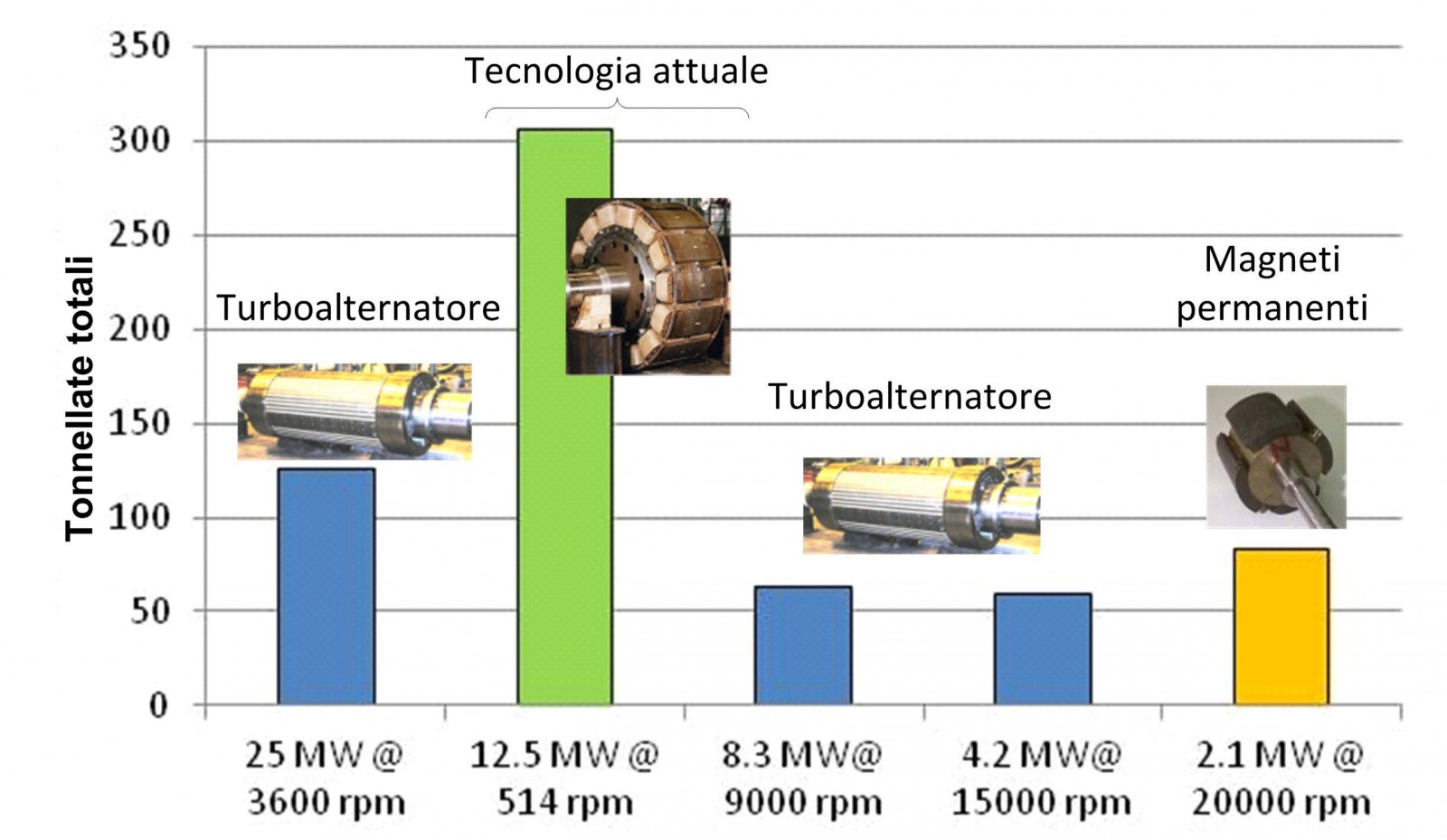

The possibility of increasing speed by using gas turbines instead of traditional low-speed internal combustion engines leads to dramatic reductions in the size and weight of electric generation machinery. Throughout the project, detailed dimensioning scenarios were investigated with respect to various ratings and speeds. As an example, for a power rating of around 12 MW (similar to that of today’s low-speed alternators), increasing the speed from 500 rpm (typical of a large internal combustion engine) to 9000 rpm (typical of a gas turbine) can reduce the size and weight of the electric generator to almost one-tenth compared to the traditional technology currently in use.

Overall weight estimate for electric generators to be taken on board for different possible machine technology to fulfill the same total power demand.

Reliability

The electric generator, combined with power electronics converters for an MVDC network supply, is well suited to multiphase topology design. These topologies use not only single- but also multiple stator windings, each connected to a different power converter. The generator-converter assembly thus has a highly modular architecture in which, if one module fails, the rest of the system can continue operating, although with slightly degraded performance.

MVDC Large Ship – Sistema elettrico integrato con distribuzione in media tensione a corrente continua per grandi navi a propulsione elettrica, è un progetto cofinanziato dal POR FESR 2007-2013 Regione Friuli Venezia Giulia, Asse 1, Attività 1.1b.